Thermal printing technology prints without the need for ink or ribbon by controlling the heating elements of the print head and using special thermal paper or labels. This technology is widely used in retail, logistics, medical and other industries, and is widely welcomed because of its simplicity, high efficiency and energy saving.

Thermal printing technology has become an indispensable part of modern commercial applications because of its simplicity, efficiency and environmental protection. By integrating advanced hardware and software technology, this scheme provides reliable printing solutions to meet the needs of various industries for high-quality and efficient printing, while reducing operating costs and environmental impact.

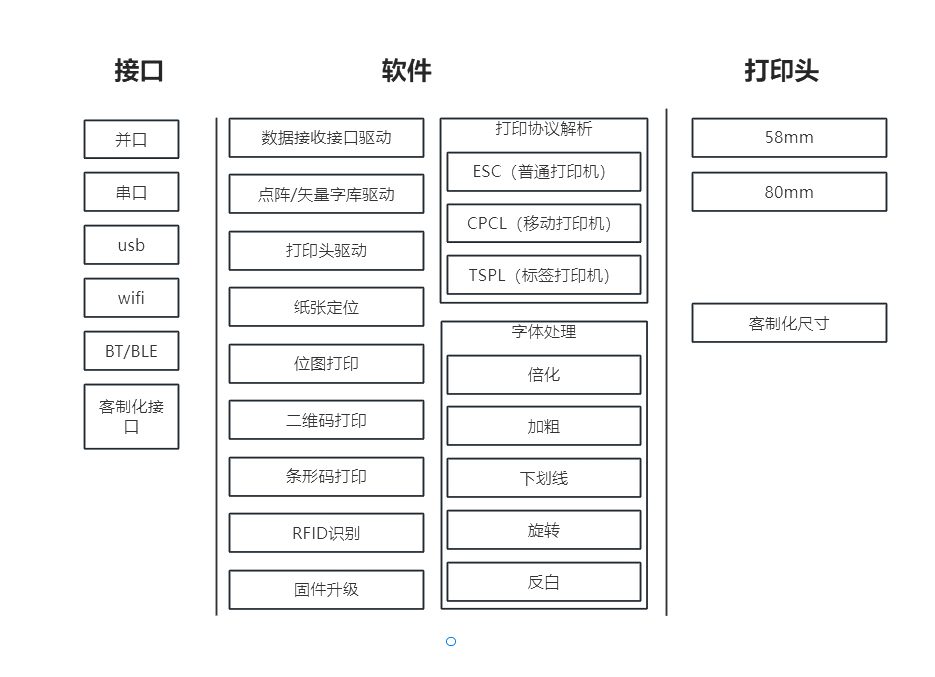

As you can see from the above picture, the thermal printer is mainly divided into the following three parts

1. Communication interface

Here we can use different interfaces as the medium to transmit print data. Sirui thermal printer solution currently supports serial / parallel / Bluetooth / wifi/usb interface, printing protocol supports ESC, if you need customization, please contact.

two。 Print data processing

After receiving the data, the thermal printer will judge whether it is the instruction or the text content, if it is the text content, then read the font data directly for font processing, and if the judgment is an instruction, then carry on the corresponding processing, the general portable thermal printer because it is connected to the APP, so there is no font requirement, then use the raster instruction of ESC to print. 3. Print head drive

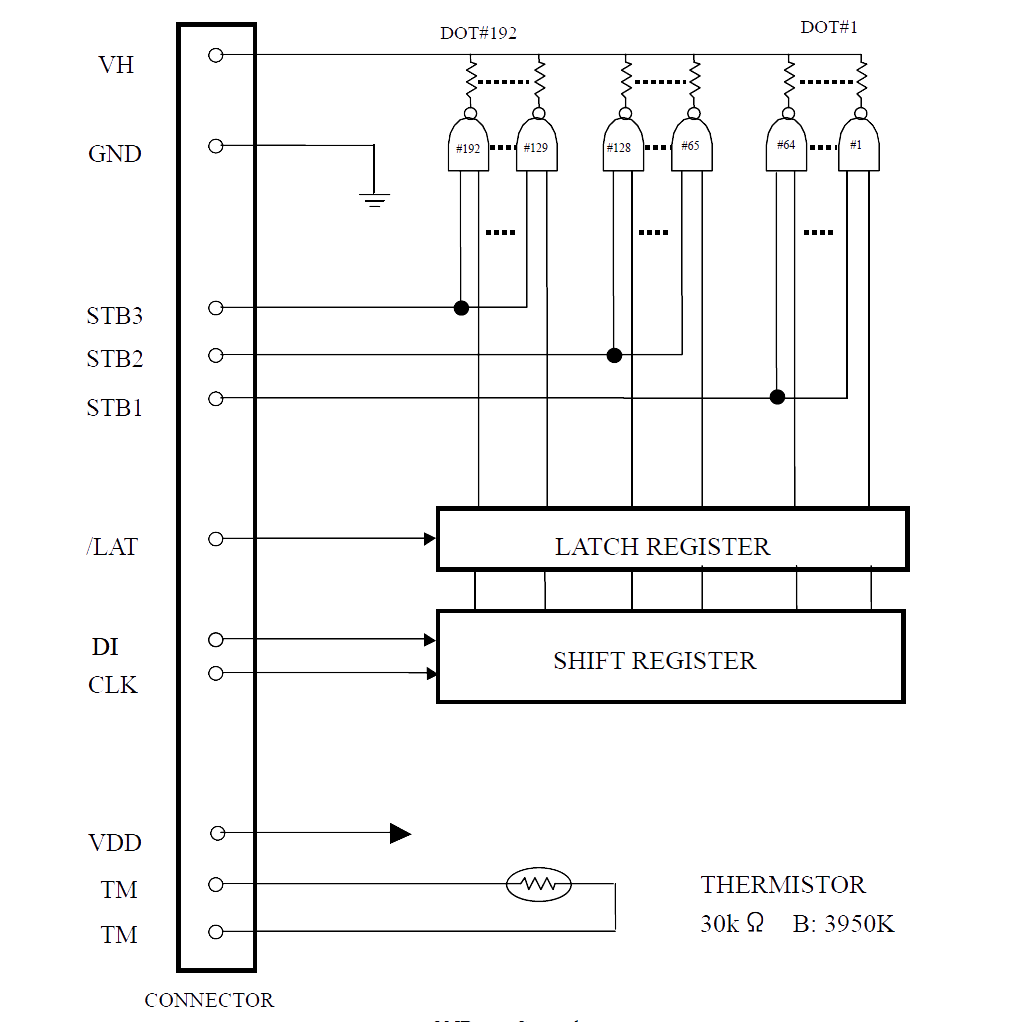

As you can see, the above picture is the circuit diagram of the print head, including the voltage VH used for heating and the ground GND. According to the size of the print head, the heating signal line STBx will be different, usually a group of STB, as well as LAT, DI and CLK for transmitting print data, and finally, the VDD power supply for internal operation and the print head temperature sensor TM are provided.

● printhead width: 9mm-219mm

● print density: 8dot/mm (203dpi) / 12dot/mm (300dpi) ● print speed: 50mm/s-150mm/s

● communication interface: serial / parallel / Bluetooth / wifi/usb

● support instruction set: ESC ● consumables binding: support

The above picture shows the timing of data transmission in the printhead, you can see the relationship between CLK and DI, and its driver peripherals can be transmitted by SPI. Each line of data transmitted will pull down the LAT signal for signal latching, and then enable STBx to heat up, thus completing a line of data printing.

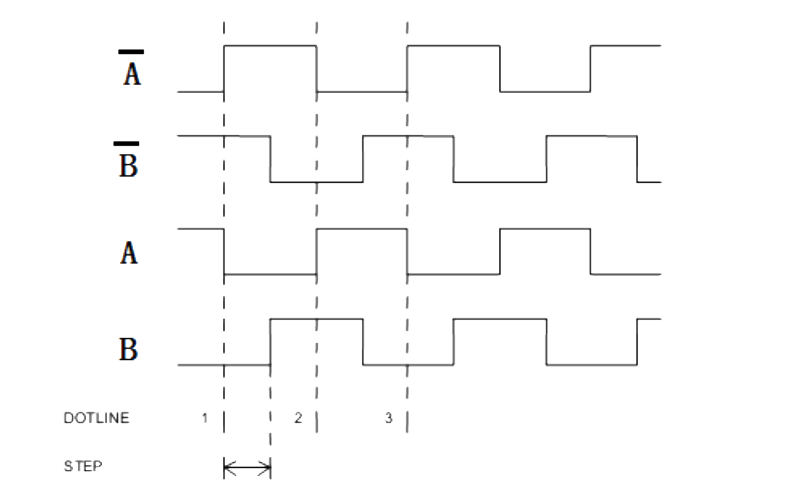

The picture above shows the driving time sequence of the stepper motor. The thermal printer sends a current pulse signal to the motor, which causes the stator coil to generate current and the corresponding magnetic field, which causes the rotor to rotate. Each time a pulse signal is input, the rotor rotates a fixed angle, which is called the step angle. By continuously inputting the pulse signal, the continuous rotation of the motor can be realized.

Retail industry: commodity labels, receipt printing.

Logistics industry: package labels, transport documents printing.

Medical industry: medical record label, prescription label printing.

Home industry: label printing

Education industry: wrong question machine

Contact us

Contact us